MEASUREMENT & VALIDATION

Proving Effectiveness Through Evidence and Discipline

UVC technology does not work by presence alone.

Its effectiveness depends on measurable factors that must be verified, monitored, and maintained over time.

Measurement & Validation exists to explain how UVC performance is evaluated, why assumptions are insufficient, and how responsible use depends on evidence rather than expectation. This page establishes the principles that separate perceived effectiveness from proven effectiveness.

WHY MEASUREMENT MATTERS

UVC systems are often discussed in terms of capability, but capability alone does not guarantee outcome.

Environmental variables such as distance, airflow, surface geometry, humidity, and system aging can significantly influence performance. Without measurement, these variables remain unknown, and performance becomes assumed rather than confirmed.

Validation ensures that UVC systems are not only present, but functioning as intended — safely and effectively.

DOSAGE & COVERAGE

UVC effectiveness is determined by dose.

Dose is the result of intensity and exposure time delivered to a target area.

Coverage refers to how uniformly that dose reaches the intended space, surface, air stream, or volume of water. High intensity without sufficient coverage can leave untreated areas. Broad coverage without adequate dose can reduce effectiveness.

Distance, shadowing, movement, and obstructions all influence dosage and coverage. In air systems, airflow speed and turbulence play a major role. On surfaces, angle and material properties matter. In water systems, clarity and flow rate affect exposure.

Understanding dosage and coverage requires more than theoretical calculation. It requires real-world measurement.

WHY DOSE CANNOT BE ASSUMED

Assumptions are one of the most common sources of UVC failure.

Lamp output changes over time. Surfaces accumulate residue. Airflow patterns shift. Environmental conditions evolve. A system that performs well on day one may perform differently months later if not monitored.

Measurement transforms UVC from a static installation into a managed system.

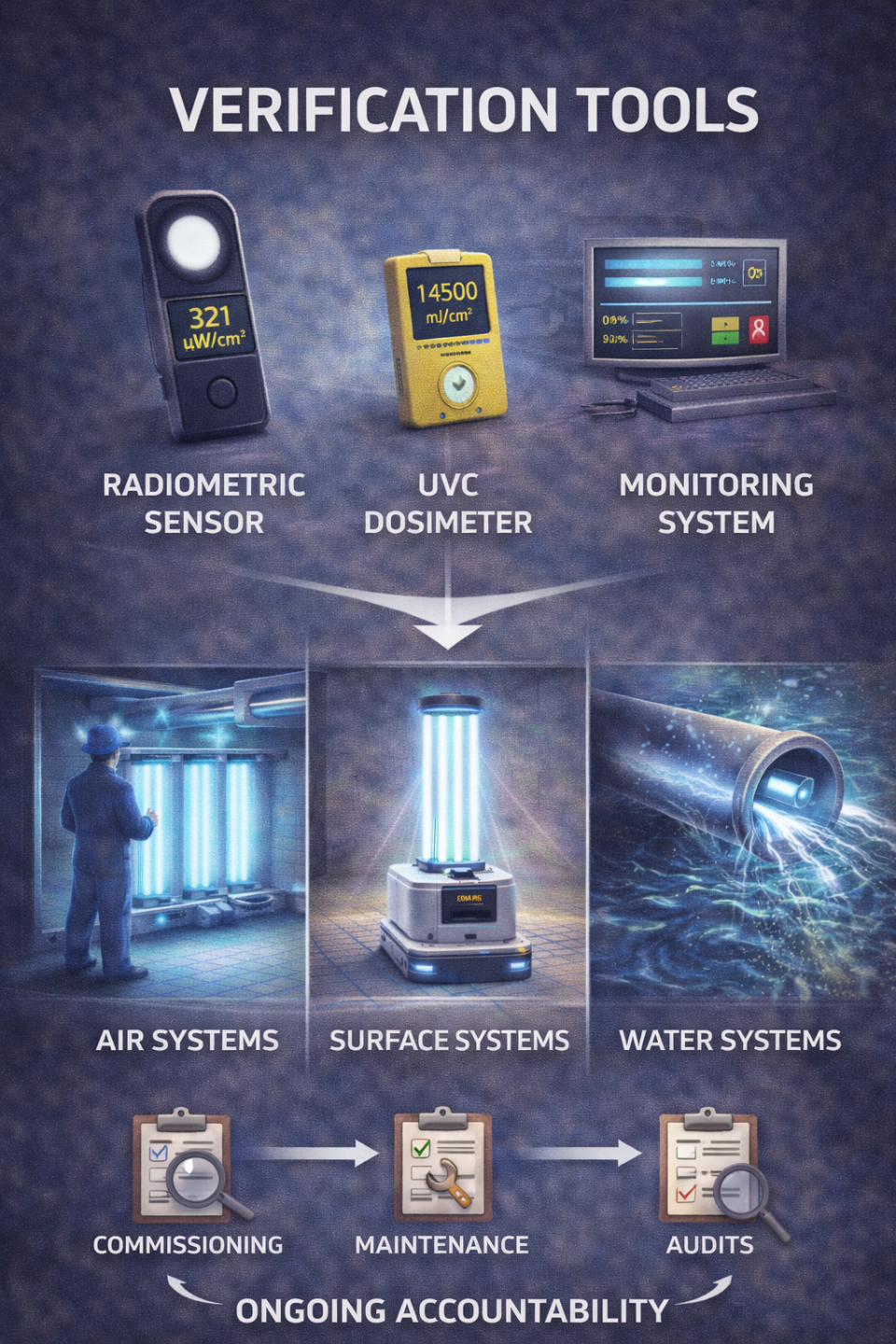

VERIFICATION TOOLS

Verification tools are used to confirm that UVC systems are delivering the intended dose within defined safety boundaries.

These tools may include radiometric sensors, dosimeters, monitoring devices, and system diagnostics that assess output, distribution, and operational status. Verification may occur during commissioning, routine maintenance, or periodic audits.

Tools vary by application. Air systems, surface systems, and water systems each require different validation approaches. No single tool applies universally.

Verification is not a one-time event.

It is part of ongoing accountability.

MEASUREMENT AS A SAFETY FUNCTION

Measurement does more than confirm effectiveness.

It also supports safety.

By confirming output levels and operational behavior, measurement helps ensure that exposure limits are not exceeded and that systems remain within design parameters. This dual role — validating performance while protecting people — makes measurement central to responsible UVC use.

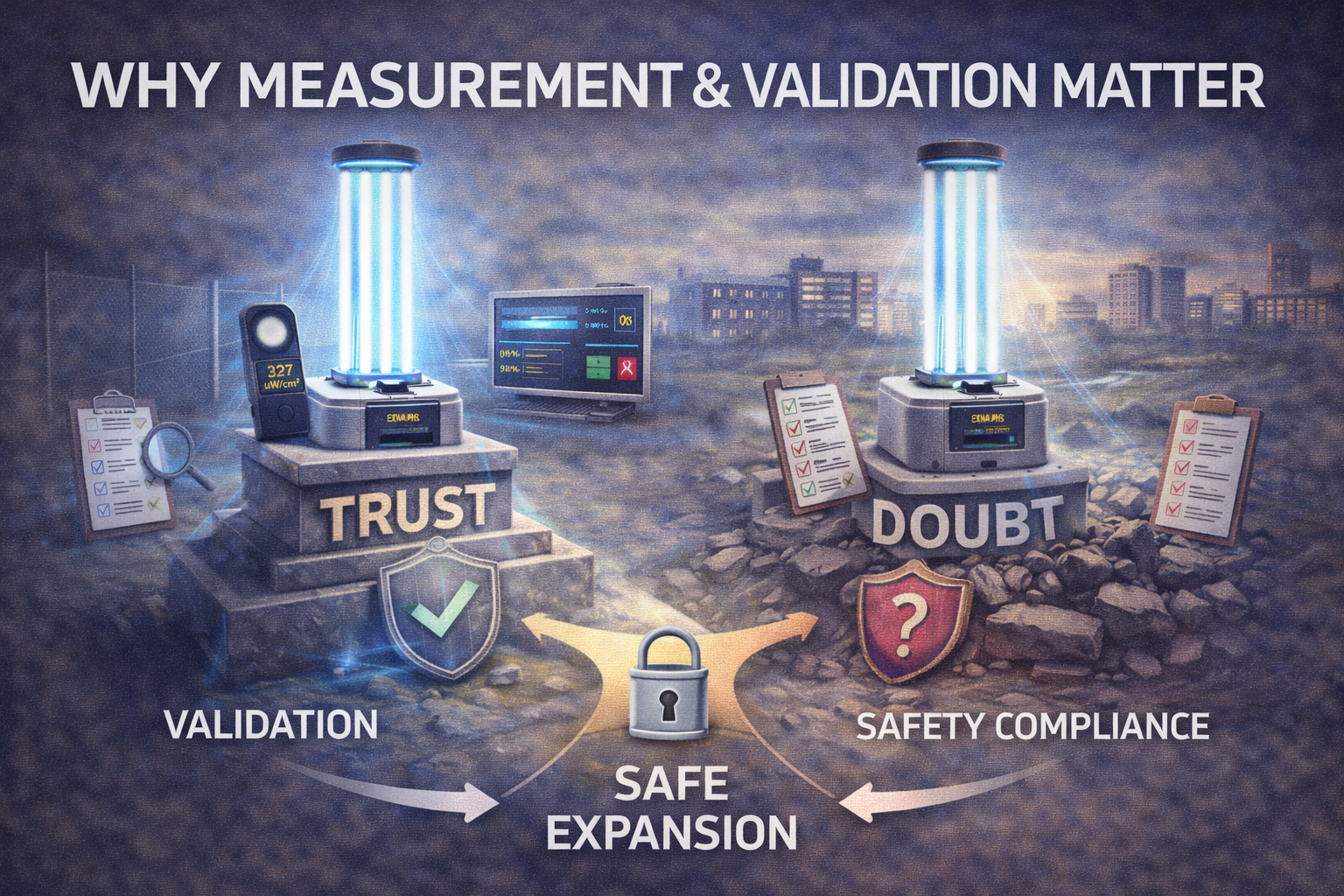

ACCOUNTABILITY OVER CONFIDENCE

Effective UVC deployment relies on humility as much as confidence.

Measurement acknowledges uncertainty and replaces it with evidence. Validation replaces assumption with proof. Together, they support informed decisions, corrective action, and long-term trust in UVC technology.

Without measurement, confidence is fragile.

With validation, confidence is earned.

WHY MEASUREMENT & VALIDATION MATTER

UVC systems that are not measured cannot be trusted — regardless of intent or design.

Measurement and validation protect people, support safety compliance, and ensure that UVC technology delivers meaningful value rather than perceived reassurance.

This discipline is what allows UVC to move responsibly from controlled environments into broader use.

UVC Today — Measurement & Validation

Evidence over assumption.

Discipline over guesswork.

Trust through verification.